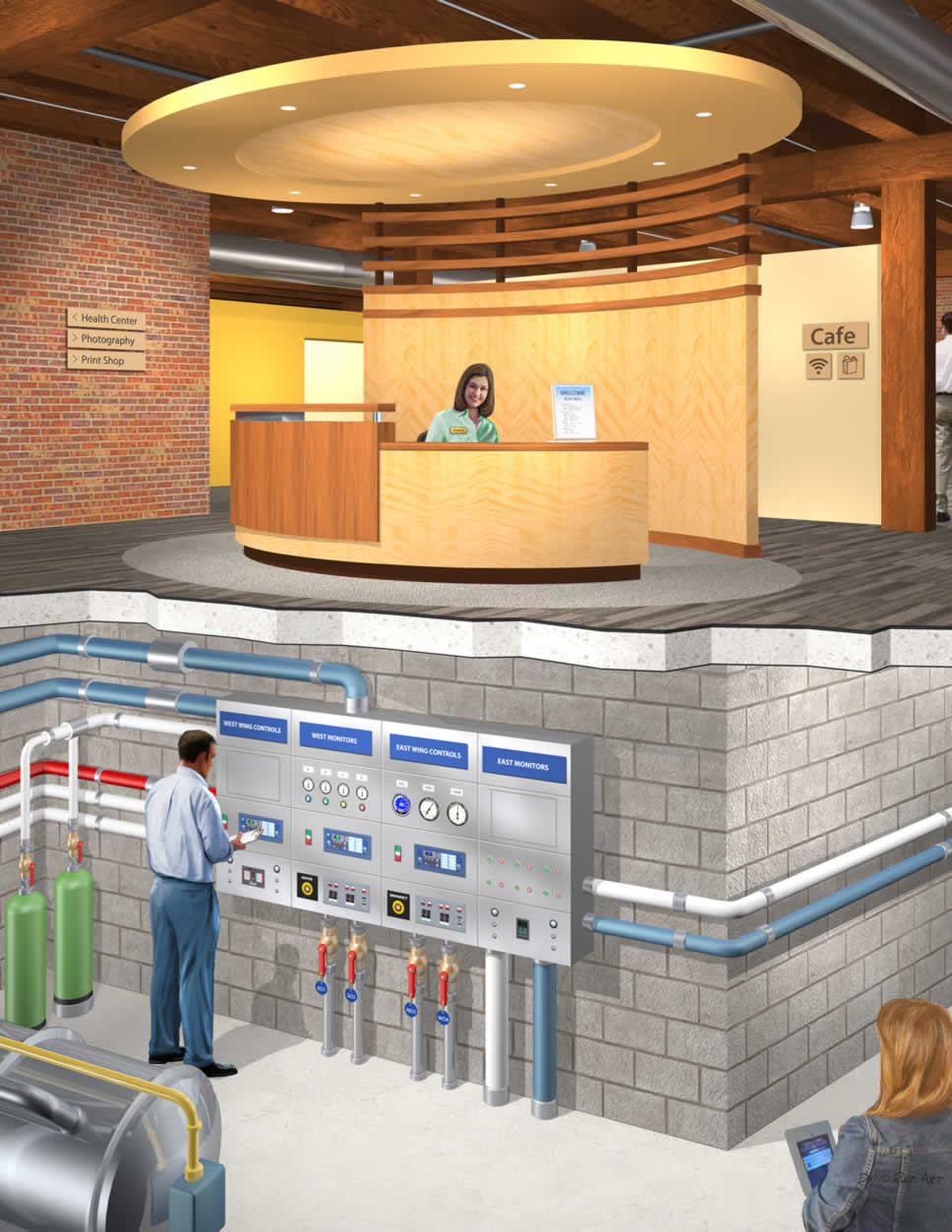

A fresh start & a new combination -- Engraving Machine & Software

Sometimes adding one new feature after another to a product can create more confusion than benefits. You end up with a horse designed by a committee. And that’s what most of the engraving systems on the market appear to be – functional, but far too complicated.

We believe a completely fresh start is the better alternative. A new machine. New software. The latest concepts. Introducing our fully integrated Scott SignGraver machine and SignGraver Manager software…with a focus on ease of learning, ease of use, higher productivity.

By reducing your labor costs and time lost to learning, operating and do-overs, our revolutionary machine ultimately pays for itself – consistently and continuously. Everything is bundled for you, from ready-to-engrave example files, to cutters, materials and more. So let’s get started!

A benchmark benchtop engraving system

That emphasis on greater work productivity is easily recognizable in our new benchtop engraving system. The functional design promotes a neat and clean workspace, with managed wires and a handy vacuum that fits naturally into a knee-hole beneath the bench, where it’s attached via clear flex tubes. No ifs, ands, bolts or clutter.

A separate, dedicated program is used to design signs and create engraver-ready files. Our own SignGraver Manager software imports those files and runs the engraver. The software features pre-set specifications for engraving cutters, burnishing tools and scribes.

And this is actually software that learns! Should you ever want to alter the standard specifications, the software memorizes your preferences and automatically edits the standard specs to your new selections.

Learn It and Turn It in Just an Hour

Since this machine is designed to save you time and effort, let’s set a time of one hour from crate-to-completion of your first sign.

Your machine arrives with a half-engraved sign in place on the GripNGraver nanotac mat, and an engraving cutter is already installed. Follow each step in the video, and soon you’ll have your first engraving sign in hand. Done in under an hour? See for yourself!

Make Every Name Hard to Forget

Most clients purchase ready-made sign and name tag blanks from us, to make fast work of creating signs when they need them. Here we position a ready-made name tag blank on the bed, press, engrave, then lift it from the corner when done.

Take a close look at the engraving – its crisp edges and bright white letters. Valve tags, serial number plates, electric equipment labels – keep the blanks in your inventory and engrave what you need on-the-spot. What’s the overriding concept for our fresh engraving system? Your productivity!

A multi-line engraving font is used on the top line and a single-line font is used on the second line. Learn more about

Engraving to Profiling - No Need to Fear Change

We’ve already engraved the letters in the center of this plastic panel. Now we want to cut out the tag. To create engraved items with a custom profile – name tag, serial number plates, valve tags, electrical circuit labels – we use a profile cutter. And guess what…our quick-change spindle allows changes in seconds!

The SignGraver spindle accommodates all types of engraving, from engraving and profiling cutters to burnishing tools and scribes. To move quickly from one to another, select a few types of tools, pre-set their depths and keep them at hand.

For Pro Quality Profiles

A profile cutter is the preferred tool for cutting through engraving plastic, to create a custom shape and hole. Unlike a pointed-end cutter for engraving letters, a profiling cutter features a flat end and vertical sides that produce clean and straight, rather than slanted, cuts through the material.

Profile cutting is usually done in three passes through the material, to ensure a perfectly smooth edge on both the top and bottom surfaces. This meticulous approach preserves the integrity of both surfaces.

Practice It Once, Perfect It Soon After

Time is on your side, because you save plenty of it with one of our remarkable engraving machines. In fact, you’ll engrave your first legend plate…and each one after that…with ease. A GripNGraver™ nanotac mat comes with every machine, and the engraving cutter is already installed.

Simply follow the easy steps in the video, and soon your legend plate will be equipment-ready. Let’s give it a try!